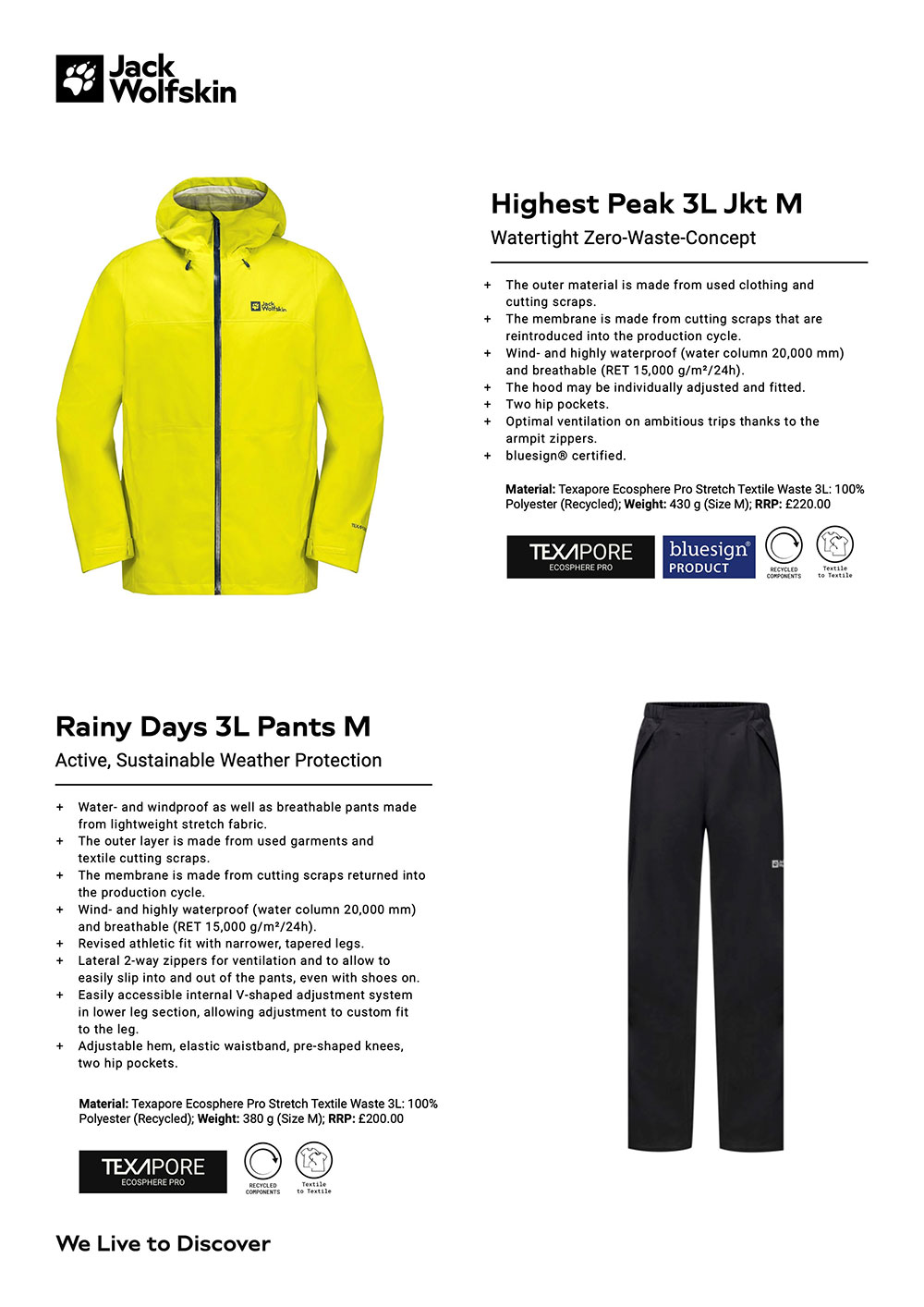

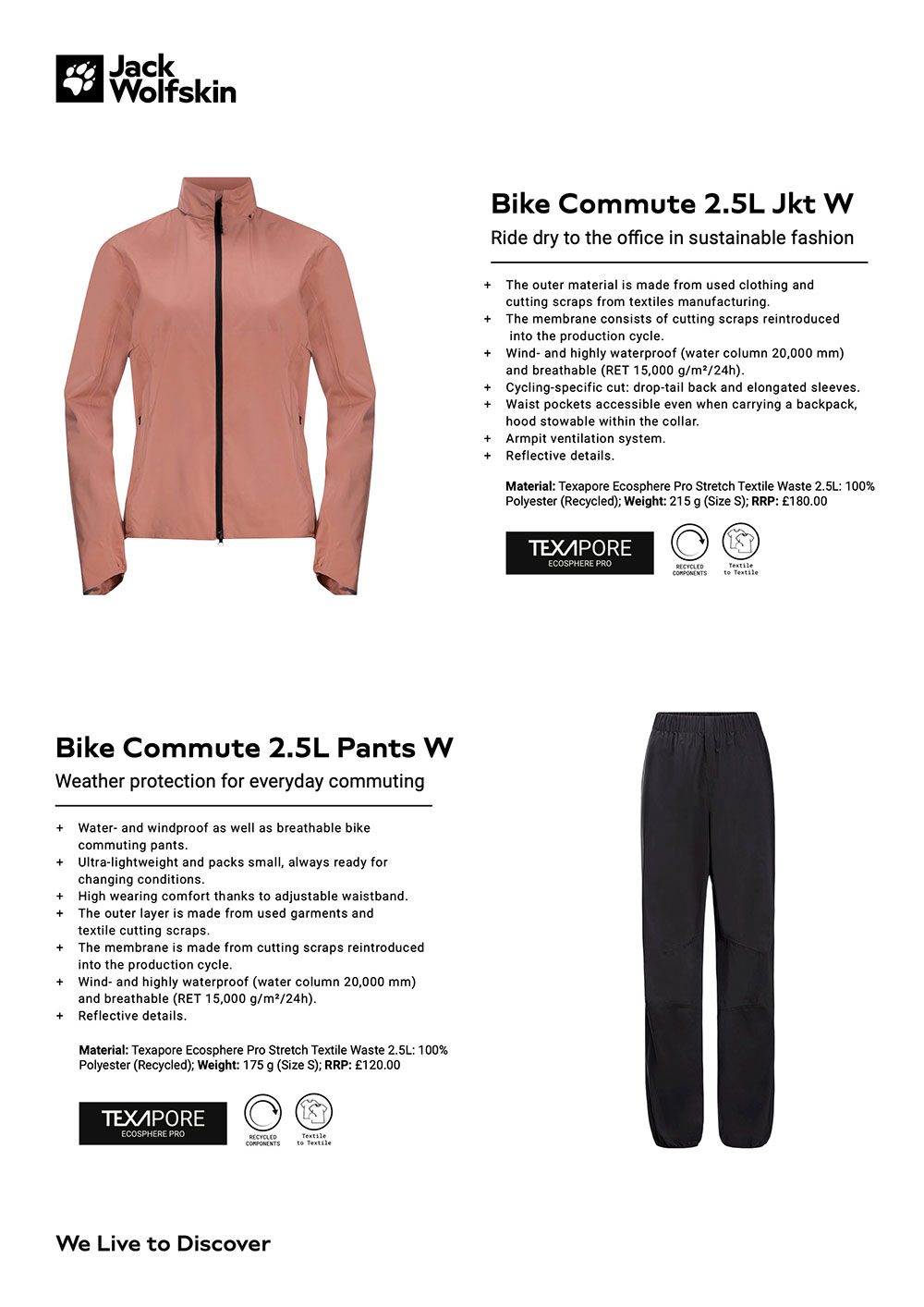

However, the Idstein, Germany-based pioneer of sustainability is dedicated to achieving a true circular economy - in other words, to produce highly functional garments from discarded clothing as well as from cutting scraps and from material residues that arise during production. With its 'Textile to Textile' concept, Jack Wolfskin has now accomplished this goal: eleven styles of the 2024 summer collection feature an outer shell made from recycled textiles.

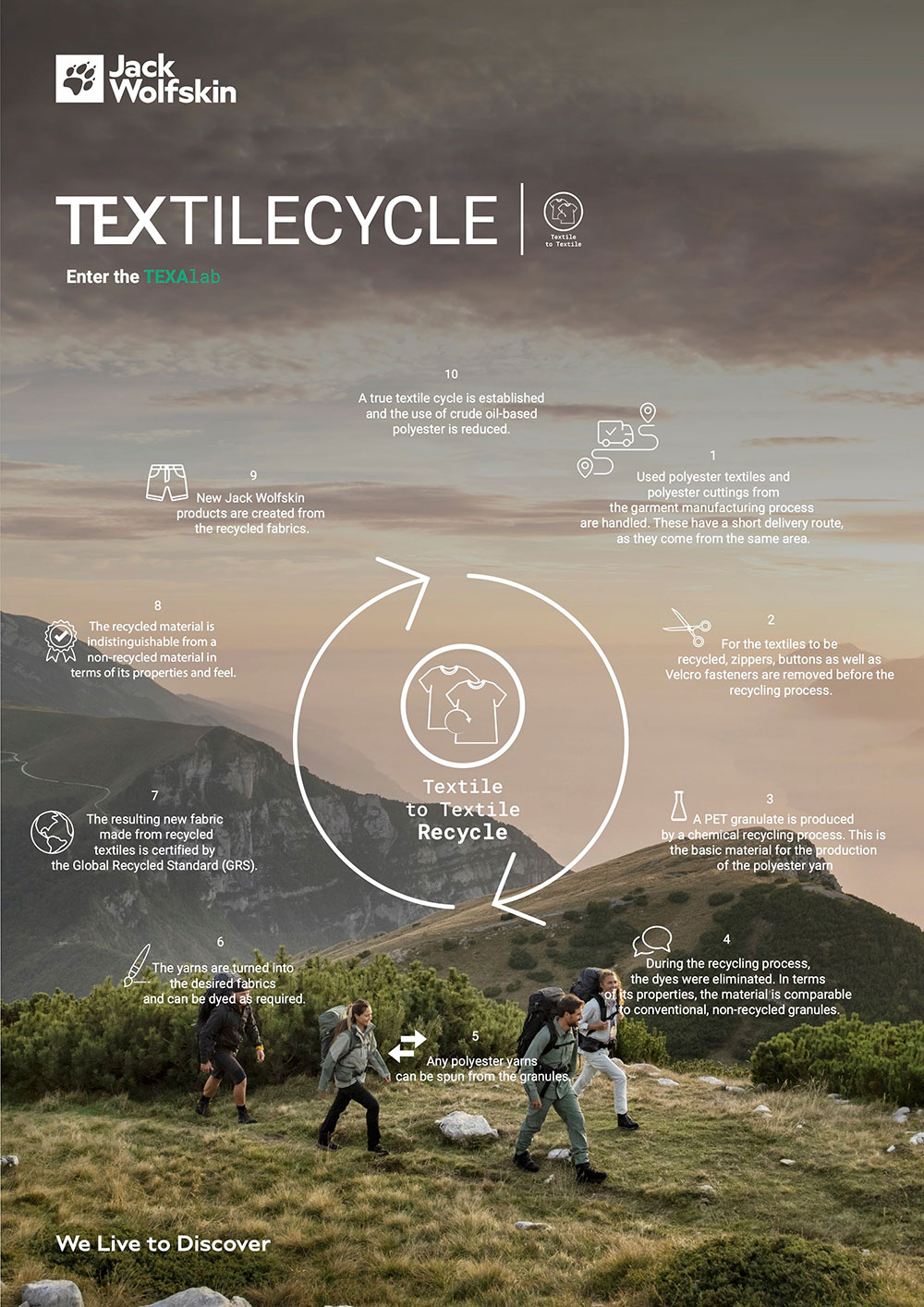

In Textile to Textile recycling, used garments first are stripped from non-textile materials such as zippers. They then are chemically processed, along with cutting scraps, into a PET granulate, which in turn is spun into polyester yarns. This chemical process also removes dyes so that the yarn may be re-dyed. The final product is recycled material that in terms of its properties performs just as well as crude-oil-based virgin polyester. The self developed Texapore Ecosphere membrane guarantees maximum protection and optimum comfort. It is made from offcuts that are generated during production and fed back into the production cycle - a zero-waste concept. After all: whether you‘re hiking or commuting by bike, functionality and sustainability go hand in hand at Jack Wolfskin.